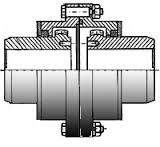

GEAR COUPLINGS

Customers who are in search of an alternative to a universal joint application are in need of a mechanical device for transmitting torque between two shafts that are not collinear. This is called a “Gear Coupling.”

Gear couplings and universal joints are used in similar applications but gear couplings have higher torque ratings than universal joints and are designed to fit a given space. The torque rating of universal joints is limited by design due to its cross sections. A gear coupling is designed with gear teeth which have high backlash to allow for angular misalignment, this provides flexibility, higher torque rating and maximum surface to surface contact to transmit torque.

Flexible Coupling

Couple or connect rotating members such as motors and drive shafts, while allowing misalignment in either angular or parallel offset orientation. Coupling types can be sliding back, roller or silent chain. When searching for flexible couplings some mechanical properties are to be considered. These include rated torque, rated speed, torsional stiffness, and backlash. Rated torque is the maximum service torque for which a coupling is rated. The rated speed is the maximum rated rotational speed of a coupling. Stiffness is expressed in torque per unit of angular deformation. Backlash is the rotational position loss due to a direction change.

Rigid Coupling

Connect or couple rotating members such as shafts. Rigid Couplings secure onto both members and provide transmission of torque and motion. They do not allow for angular or parallel misalignment.

Mounting

There are many methods to mount couplings on a shaft. For motors with access to the rear end of the shaft, couplings can be pressed directly onto the shaft. Another method is to secure couplings to the shaft with a setscrew. The presence of a flat on the shaft helps prevent slipping. It can also be mounted with the help of adhesives. Adhesive should be applied to the couplings and not to the shaft directly. Couplings can be pinned by drilling a cross-hole across the shaft.

Speak with a friendly Machine Service, Inc sales engineer and we can provide a gear coupling to suit your specific application requirements.